Geosynthetics are manmade synthetic materials made of polymeric or natural materials in the form of a sheet, a strip or a three-dimensional structure. Geosynthetic products are primarily mixed with soil and rock, or any other related geotechnical engineering materials for civil engineering, transportation, coastal/hydraulic/water resources, mining and environmental applications. In these applications, geosynthetics serve several functions such as separation, filtration, drainage, reinforcement, protection (by way of cushioning), containment, erosion control and waterproofing.

Geosynthetic products

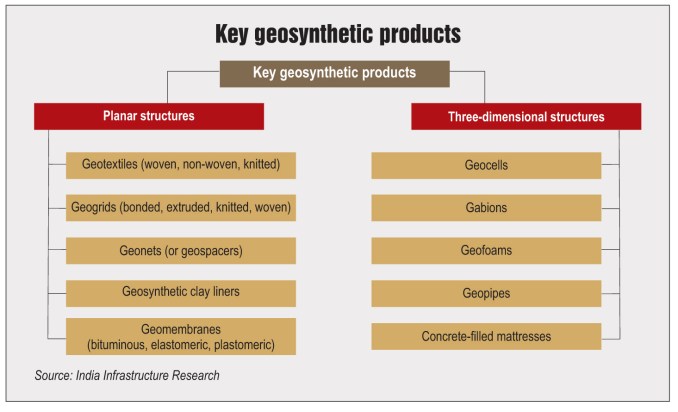

Geosynthetics comprise a range of planar and three-dimensional structures. There are nine main product categories – geotextiles, geogrids, geonets, geomembranes, geosynthetic clay liners, geopipes, geocells, geofoams and geocomposites.

- Geotextiles: These are textiles consisting of synthetic fabric instead of natural materials (cotton, wool, silk, etc.) which makes them less prone to biodegradation. The synthetic fibres can be made into a flexible, porous, non-woven, needle-felt fabric. Geotextiles are porous to water flow, but the extent of porosity varies. They are usually made from polymers such as polyester (PET) or polypropylene (PP). They can be further divided into three categories – woven fabrics, non-woven fabrics and knitted fabrics. Depending on the function, they are used in open-mesh versions, such as a woven or warp-knitted structure, or with a closed fabric surface, such as a non-woven geotextile.Geotextiles have proven to be among the most versatile and cost-effective ground modification materials and their use has expanded rapidly into nearly all areas of civil, geotechnical, environmental, coastal and hydraulic engineering. The products are used for reinforcement of streets, embankments, ponds, pipelines, and other similar applications. Geotextiles are the most commonly used geosynthetic product for agriculture, construction and transportation projects. In particular, they are widely used for road stabilisation via separation and drainage in cases where the native soil beneath the road has low natural strength due to being constantly wet.

- Geogrids: These are polymeric products formed by joining intersecting ribs and have large open spaces called apertures. The direction of the ribs is referred to as the machine direction (md), which is oriented in the direction of the manufacturing process. The other direction is the cross machine direction (cmd), which is perpendicular to the md ribs. Polymeric materials like PET, high density polyethylene (HDPE) and PP are the main constituents of geogrids, which are primarily used for soil reinforcement of unstable soil and waste masses. These products act as a solution for the construction of roads, highways, pavements and other structures on soft or problematic subgrades that previously needed expensive piling methods.

- Geonets: They are usually formed by a continuous parallel set of polymeric ribs at acute angles to one another forming a net-like configuration with opening of ribs. Their design function is completely within the drainage area where they are used to convey fluids of all types. The major applications of geonets are in landfills, foundation walls, methane roads, asphalt concrete pavements, erosion control, drainage, etc.

- Geomembranes: These are thick impervious plastic sheets with a thickness of 0.5-3 mm used primarily for linings and covers of liquid or solid storage facilities. Geomembranes are used to control fluid movement and are highly impermeable unlike geotextiles, geogrids and geocells. Thus, the primary function is containment as a liquid or vapour barrier or both and finds applications in land, pond/canal and tunnel lining projects. However, geomembranes are relatively more expensive in unit terms as compared to other geosynthetic products.

- Geosynthetic clay liners: These are rolls of factory-produced material mostly consisting of two layers of non-woven geotextiles with an intermediate layer of sodium bentonite powder. The two layers of geotextiles are joined together by a sewing process (needle- punched non-wovens), thus creating a perfect stable mat with high internal shear resistance. On contact with water, the sodium bentonite in the mat swells up and creates a waterproof mineral layer. Geosynthetic clay liners act as a barrier system in municipal solid waste landfill applications. Typical lining applications of the material include use in canals, stormwater impoundments and wetlands, secondary containment, highway and civil construction, landfill liners, landfill caps, mines, etc.

- Geopipes: Geopipes, or buried plastic pipes, are mainly used in drainage applications. They are primarily used for leachate collection and in case of high compressive loads.They can also be used in landfill applications to facilitate collection and rapid drainage of the leachate to a sump and removal system.

- Geocells: Geocells, or cellular confinement systems, are three-dimensional systems fabricated from ultrasonically welded HDPE strips that are expandable on-site to form a honeycomb-like structure. They are filled with compact non-cohesive soils which are confined within the cellular walls and the composite forms a rigid to semi-rigid structure. Geocells are perforated to enable passage of water and thus dissipate internally generated pore pressure. They are widely used in construction for erosion control, soil stabilisation on flat ground and steep slopes, channel protection, and structural reinforcement for load support and earth retention.

- Geofoams: These are rigid, engineered, lightweight fill materials typically made of expanded polystyrene (EPS). As a fill material, a key advantage of EPS geofoam is its weightlessness. The primary function of a geofoam is to provide a lightweight void fill below a highway, bridge approach, embankment, etc. Geofoam can be an ideal solution in the reduction of lateral and dead loads over buried utilities (underground pipes, culverts and tunnels).

- Geocomposites: Geocomposites comprise a combination of any three of the geosynthetic materials – geotextiles, geogrids and geomembranes. They are primarily used for separation, reinforcement, filtration, drainage and containment. The application sectors are many and are constantly growing.

Advantages of geosynthetics

Advantages of geosynthetics

Geosynthetics have economic significance for several reasons. They are commonly accepted as being durable and environmentally safe solutions for geotechnical engineering projects, and comprise 3-5 per cent of the total project cost. Reportedly, savings of around 30 per cent have been noted in a number of projects. Their use has a direct impact in terms of minimising regular repair and maintenance costs. Besides, they prevent accidents, increase efficiency of structures, minimise pollution and lead to efficient use of natural resources.

Besides economic importance, geosynthetics are pertinent from an environmental point of view. They provide long-lasting solutions, which are important for civil engineering structures that require long-term durability in order to limit the effect of ecological disasters (floods, earthquakes, global warming). Geosynthetics are difficult or impossible to degrade. They also act as a containing barrier for toxic materials. They are highly durable – in many cases their life has been reported to be over a hundred years. Besides, geosynthetics provide sealing and capping of pollution due to chemicals released into groundwater areas after road and rail accidents.

Conclusion

Conclusion

The use of geosynthetics in infrastructure construction offers multiple benefits. With increased investment spending, geosynthetic products have become well-established construction materials in most parts of the country. Geosynthetics are a blessing for engineering construction as their use reduces land requirement and in many cases leads to safer design with a lower carbon footprint. Though geosynthetics are currently underutilised in the country as compared to global deployment, going forward, their use in the infrastructure sector is bound to grow exponentially primarily due to the government’s thrust on infrastructure development, changes in environmental regulations and increasing land scarcity.